R Values and Material Thickness

The resistivity of a material is measured based off its thickness and what it is made of to give an R value. The R Value shows how well the material is able to resist heat over an area of exposure. It is measured in m2 K/W and relates to temperature, energy, and exposure. The R-value tells you how many degrees of temperature difference you can maintain across one square meter of material for every one Watt of heat flowing through it.

This is important when dealing with high temperature applications because we want to know how much temperature we can put through a material before it starts to cause problems on the other side. A low R value means that the materials will have less resistance compared to a high R value.

If we want to compare materials we can use the R value of the alternative material to work out the thickness required to achieve the same measurement. To do this we must make the R value dimensionless (i.e. get rid of the m2 component) so we divide the material thickness by the R value, which leaves us with the dimensionless thermal conductivity value K (K=L/R)

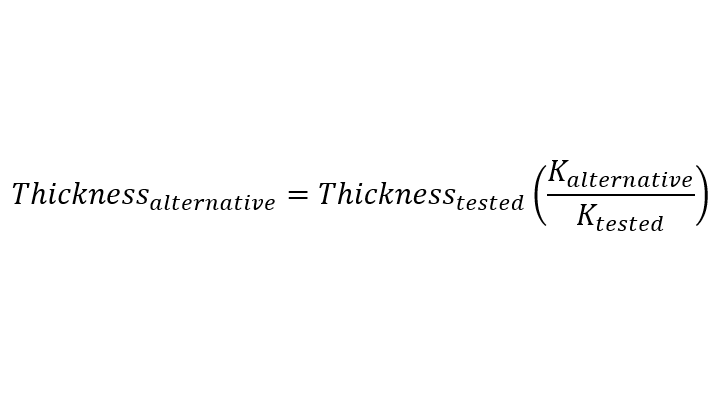

As it is now dimensionless we can use it to compare to other materials K value. Once we now have a thermal conductivity measure of the tested material and the alternative we can then use the two to give a ratio to work out how much of the alternative material we need. This is done by: Thicknessalternative = Thicknesstested(Kalternative/Ktested)

i.e. If we have Hebel which has an R value of 0.53 at a thickness of 75mm. This gives a K value of 0.075/0.53 = 0.141. If we want to use Hardiflex panel which has a K value of 0.23 at 15mm thickness we use: 75mm(0.23/0.141 = 122mm thickness.

This means we need 122mm of the Hardiflex panel to give the same resistance as Hebel Block.

This is important when dealing with high temperature applications because we want to know how much temperature we can put through a material before it starts to cause problems on the other side. A low R value means that the materials will have less resistance compared to a high R value.

If we want to compare materials we can use the R value of the alternative material to work out the thickness required to achieve the same measurement. To do this we must make the R value dimensionless (i.e. get rid of the m2 component) so we divide the material thickness by the R value, which leaves us with the dimensionless thermal conductivity value K (K=L/R)

As it is now dimensionless we can use it to compare to other materials K value. Once we now have a thermal conductivity measure of the tested material and the alternative we can then use the two to give a ratio to work out how much of the alternative material we need. This is done by: Thicknessalternative = Thicknesstested(Kalternative/Ktested)

i.e. If we have Hebel which has an R value of 0.53 at a thickness of 75mm. This gives a K value of 0.075/0.53 = 0.141. If we want to use Hardiflex panel which has a K value of 0.23 at 15mm thickness we use: 75mm(0.23/0.141 = 122mm thickness.

This means we need 122mm of the Hardiflex panel to give the same resistance as Hebel Block.