Vogue Heaters: A Unique 3 Burn Cycle

For over ten years, Mr Stoves Vogue heating range has been a market leader in wood heating technology. The Vogue Navara is one of the most efficient and environmentally friendly wood heaters on the market.

So ahead of the field was it, that it won an Australian Design award in 1992 for its completely unique and revolutionary features. But what exactly makes the Vogue Range so unique from every other heater on the market, you may ask?

Available only at Mr Stoves, our Vogue heaters employ a unique 3 burn cycle into all their heaters. This 3 burn cycle technology allows it to:

Start faster Burn longer Be environmentally friendly

How does our Unique 3 Burn Cycle Work?

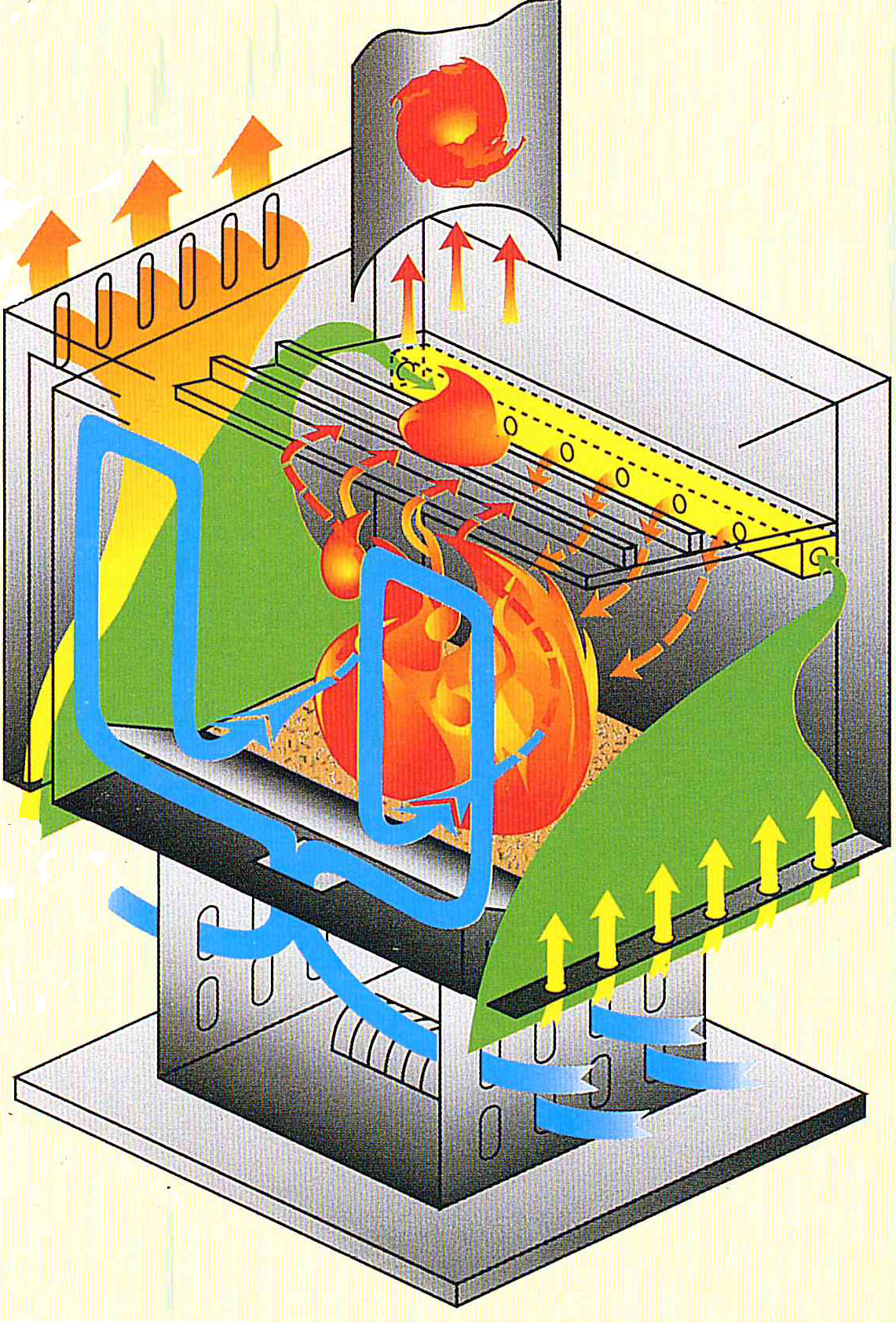

Primary air is introduced into the heater through the ventilated side panels of the pedestal. This primary air (BLUE) is preheated as it travels upwardly through the primary manifold, around the front of the firebox and is injected down into the firebox from above the door class.

The principal reason for this overhead direct air injection is primarily to draft down over the internal glass door creating a draft vortex, thus allowing the flame to feed oxygen upwardly against the glass utilizing the washing abrasive turbulence to remove any tar, sap or carbon deposits from the combustion process. THE DOOR GLASS REMAINS EXTREMELY CLEAN.

This blue primary air continues down the glass, the draft vortex aided by the front deflection baffle (located directly below the door) helps direct this air stream into the base of the fuel load generating spontaneous high yield combustion.

Secondary air (Green) is injected from the pressure manifold located at the upper rear section of the firebox just below the baffle plate. Its function is to supply secondary air aimed directly into the spent gases at the top of the primary combustion chamber. The oxygen enriched has is reignited at the top of the firebox removing further unburnt tar and sap (creosote).

Tertiary Burn is where any unburnt gases are directly over the baffle plate where they are compressed, remixed with fresh air and rapidly expanded and burnt prior to their exhaust into the flue system.

The inner firebox with its state of the art combustion technology is encased inside a double skinned ventilated cabinet- thus allowing cool fresh air (Yellow) to flow upwardly through large vent holes at the base of the cabinet between the inner panels conducting most of the inner fireboxes' heat into a continuous stream of warm naturally flowing ORANGE convection air directed outwardly and away from the heater through vent holes at the top sides of this outer enamel cabinet. The result is increased heat output and as a direct safety benefit the external shell is relatively safe to touch, this also allows close proximity to furniture and rear walls.

Our technology ensures you will be getting a top of the range, quality heater. Give us a call on 3375 1464 or alternatively drop into our showroom and speak to one of our knowledgeable team members.

Available only at Mr Stoves, our Vogue heaters employ a unique 3 burn cycle into all their heaters. This 3 burn cycle technology allows it to:

How does our Unique 3 Burn Cycle Work?

Primary air is introduced into the heater through the ventilated side panels of the pedestal. This primary air (BLUE) is preheated as it travels upwardly through the primary manifold, around the front of the firebox and is injected down into the firebox from above the door class.

The principal reason for this overhead direct air injection is primarily to draft down over the internal glass door creating a draft vortex, thus allowing the flame to feed oxygen upwardly against the glass utilizing the washing abrasive turbulence to remove any tar, sap or carbon deposits from the combustion process. THE DOOR GLASS REMAINS EXTREMELY CLEAN.

This blue primary air continues down the glass, the draft vortex aided by the front deflection baffle (located directly below the door) helps direct this air stream into the base of the fuel load generating spontaneous high yield combustion.

Secondary air (Green) is injected from the pressure manifold located at the upper rear section of the firebox just below the baffle plate. Its function is to supply secondary air aimed directly into the spent gases at the top of the primary combustion chamber. The oxygen enriched has is reignited at the top of the firebox removing further unburnt tar and sap (creosote).

Tertiary Burn is where any unburnt gases are directly over the baffle plate where they are compressed, remixed with fresh air and rapidly expanded and burnt prior to their exhaust into the flue system.

The inner firebox with its state of the art combustion technology is encased inside a double skinned ventilated cabinet- thus allowing cool fresh air (Yellow) to flow upwardly through large vent holes at the base of the cabinet between the inner panels conducting most of the inner fireboxes' heat into a continuous stream of warm naturally flowing ORANGE convection air directed outwardly and away from the heater through vent holes at the top sides of this outer enamel cabinet. The result is increased heat output and as a direct safety benefit the external shell is relatively safe to touch, this also allows close proximity to furniture and rear walls.

Our technology ensures you will be getting a top of the range, quality heater. Give us a call on 3375 1464 or alternatively drop into our showroom and speak to one of our knowledgeable team members.