Australian Made Heaters - Made in Brisbane

Manufactured since 1990, Vogue has maintained its quality and improved its design. Check out the range of our timeless Australian made heaters below.

Made right here in Brisbane with Australian Steel. These heaters are designed to withstand the higher temperatures produced by Queensland Hardwood (Ironbark).

Made right here in Brisbane with Australian Steel. These heaters are designed to withstand the higher temperatures produced by Queensland Hardwood (Ironbark).

At Mr Stoves, we're passionate about finding the best wood heater, gas heater or wood cooking stove to suit your needs. We've been in the business for over 30 years, so you can trust us to provide appliances that will stand the test of time - and also bring comfort, serenity and joy to your life.

In addition to wood and gas heaters and stoves, we also supply and install reverse cycle air conditioners that have been beautifully designed and engineered to enhance your surroundings.

We believe that it's best to see, touch and learn about our products before you buy. So please use this website as a guide - and then call our expert team members or visit our Brisbane showroom to find the perfect model for YOUR home.

QBCC Act Licence No: 15111644

In addition to wood and gas heaters and stoves, we also supply and install reverse cycle air conditioners that have been beautifully designed and engineered to enhance your surroundings.

We believe that it's best to see, touch and learn about our products before you buy. So please use this website as a guide - and then call our expert team members or visit our Brisbane showroom to find the perfect model for YOUR home.

QBCC Act Licence No: 15111644

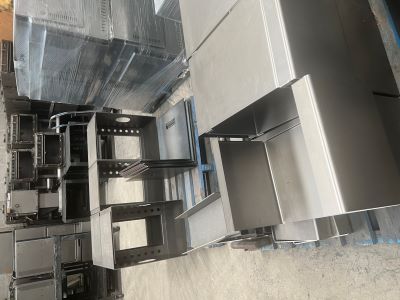

How Vogue Is Made

Materials

▼

Cutting

▼

Welding

▼

Sanding

▼

Painting

▼

Last Touches

▼

Final Product

▼

Materials

The first step in creating a high quality Australian wood heater, is sourcing high quality Australian materials. We use the best in the business, Australian Blue Scope Mild Steel. Unlike other steel, the steel we use is homogenous and therefore more durable.

Cutting

The steel is cut into different shapes and sizes for the components of the three different heaters we manufacture here.

Welding

To create a sturdy fireplace, welding is an essential step. Using heat and pressure, the different components of the fireplace are fused together and assembled.

Sanding

Once the fireplace has been assembled and welded together, we give it a good sand over to get rid of any blemishes. This is an important step to ensure a smooth surface for paint to bind to.

Painting

Now that the bare bones of the fireplace are assembled, it's time to make it look polished. Into the painting booth it goes for two coats of high temperature paint.

Last Touches

The last step in manufacturing a heater built to last 30 + years, is adding on the final components. This includes putting in the bricks, brick retainer, baffle plate, spiralled handles, and of course the door.

Final Product

The fireplace is now ready for installation or collection from our showroom in Darra.